What Is Corundum Used For

Domicile » Minerals » Corundum

Corundum

Corundum has historically been used as an annoying, only it is near famous as the mineral of ruby and sapphire.

Article by: , PhD, RPG

Corundum: Ii corundum crystal segments from India showing the mineral'south half-dozen-sided crystals with basal departing. These specimens are red in colour and might be called "ruby corundum." Prototype copyright iStockphoto / Lissart.

What is Corundum?

Corundum is a rock-forming mineral that is found in igneous, metamorphic, and sedimentary rocks. Information technology is an aluminum oxide with a chemic composition of Al2O3 and a fellow member of the trigonal crystal arrangement.

The mineral is widely known for its extreme hardness and for the fact that it is sometimes establish as cute transparent crystals in many different colors. The extreme hardness makes corundum an excellent abrasive, and when that hardness is found in beautiful crystals, you have the perfect cloth for cutting gemstones.

Natural and synthetic corundum are used in a broad variety of industrial applications because of their toughness, hardness, and chemical stability. They are used to make industrial bearings, scratch-resistant windows for electronic instruments, wafers for circuit boards, and many other products.

Corundum crystals: Photos of three corundum crystals. On the left is a common corundum from Transvaal, South Africa, that is near 6 centimeters in height. In the center is a jewel-quality carmine corundum from Karnataka, India, that is about 1.half dozen centimeters in summit. On the right is a blue sapphire corundum from Sri Lanka that is nearly two centimeters in tiptop. All three specimens and photos past Arkenstone / www.iRocks.com.

Fabricated Famous by Rubies and Sapphires

Most people are familiar with corundum; yet, very few people know information technology by its mineral proper noun - instead they know it past the names "reddish" and "sapphire." A gemstone-quality specimen of corundum with a deep red color is known as a "ruby." A gemstone-quality corundum with a bluish color is called a "sapphire." Colorless corundum is known every bit "white sapphire." Corundum of any other color is known as "fancy sapphire."

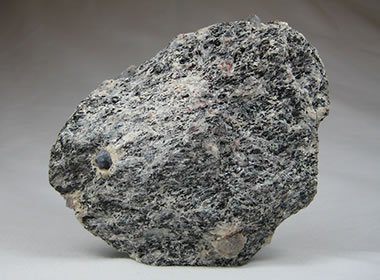

Corundum parting: 6-sided crystal segments of corundum that accept been separated by departing. These specimens are about one centimeter across. USGS photograph by Andrew Silver.

Corundum gneiss with sapphire: A specimen of corundum gneiss from Gallatin Valley, Montana. This specimen is about twelve centimeters across and has a round blue sapphire crystal on the left side.

Properties of Corundum

Corundum is an exceptionally hard and tough material. It is the third-hardest mineral, after diamond and moissanite. Information technology serves every bit the alphabetize mineral for a hardness of nine on the Mohs Hardness Scale.

Its hardness, loftier specific gravity, half-dozen-sided crystals and parting are very good diagnostic properties to employ in its identification. A summary of the physical backdrop of corundum is given in the table below.

Physical Properties of Corundum | |

| Chemical Classification | Oxide |

| Color | Typically gray to brown. Colorless when pure, only trace amounts of various metals produce almost any color. Chromium produces ruby (reddish) and combinations of iron and titanium produce blueish (sapphire). |

| Streak | Colorless (harder than the streak plate) |

| Luster | Adamantine to vitreous |

| Diaphaneity | Transparent to translucent |

| Cleavage | None. Corundum does display parting perpendicular to the c-axis. |

| Mohs Hardness | nine |

| Specific Gravity | 3.9 to 4.1 (very loftier for a nonmetallic mineral) |

| Diagnostic Backdrop | Hardness, high specific gravity, six-sided crystals sometimes tapering to a pyramid, parting, luster, conchoidal fracture |

| Chemical Limerick | Al2O3 |

| Crystal System | Trigonal |

| Uses | Historically used every bit an abrasive. Specimens with pleasing colors have a long history of gemstone use. |

Montana alluvial sapphires: A besprinkle of minor alluvial sapphires found in Montana. These blueish stones are untreated and measure out about four to five millimeters across.

Geologic Occurrence of Corundum

Corundum is found equally a primary mineral in igneous rocks such as syenite, nepheline syenite, and pegmatite. Some of the world's virtually important cerise and sapphire deposits are found where the gems have weathered from basalt flows and are now found in the downslope soils and sediments.

Corundum is also plant in metamorphic rocks in locations where aluminous shales or bauxites have been exposed to contact metamorphism. Schist, gneiss, and marble produced by regional metamorphism will sometimes comprise corundum. Some of the sapphires and rubies of highest quality, color, and clarity are formed in marble along the edges of subsurface magma bodies.

Corundum's toughness, high hardness, and chemical resistance enable it to persist in sediments long after other minerals have been destroyed. This is why information technology is often found full-bodied in alluvial deposits.

These deposits are the most of import source of rubies and sapphires in several parts of the globe. Traditional sources of alluvial rubies and sapphires include Burma, Kingdom of cambodia, Sri Lanka, India, Afghanistan, Montana, and other areas. In the past few decades, several parts of Africa, including Madagascar, Kenya, Tanzania, Nigeria, and Malawi, have get important producers of ruby and sapphire.

Emery wheels: An advertising offering emery and corundum wheels, published in 1895 past The Springfield Manufacturing Company of Bridgeport, Connecticut. This was at a time when 18-carat emery and corundum were used to make the wheels.

Hardness and Use equally an Annoying

The extreme hardness of corundum makes it especially useful as an annoying. Crushed corundum is processed to remove impurities and then screened to produce uniformly sized granules and powders. These are used for grinding media, polishing compounds, sand papers, grinding wheels, and other cut applications.

Some bug with using natural corundum as an abrasive are that the deposits are unremarkably modest, irregular in shape, and the corundum is of variable quality. They are non reliable sources of consistent-quality material needed to run a manufacturing procedure. Synthetic corundum, produced using calcined bauxite, has become a more reliable source with more consistent properties. Information technology has replaced natural corundum in most manufactured products.

Aluminum oxide sandpaper is fabricated by attaching size-graded particles of synthetic corundum (aluminum oxide) to a sheet of paper. It is a sandpaper widely used for woodworking and other manufacturing work. Photo copyright iStockphoto / Ma-Ke.

Emery stone: A specimen of emery rock that is rich in corundum and spinel from Peekskill, New York. This specimen is approximately six inches (15 centimeters) across. Emery has oft been crushed, candy, and screened for apply as an industrial annoying.

Emery nail files: "Emery boards" are a manicure and nail-care product that is made by gluing abrasive papers to a sparse piece of cardboard. They obtained their name in the 1800s when crushed emery was used as the abrasive. Today's emery boards are not made with emery. Instead, many of them have a fibroid side of synthetic corundum (aluminum oxide) and a fine side of garnet abrasive. Photograph copyright iStockphoto / Acerebel.

Emery

Emery stone is a granular metamorphic or igneous rock that is rich in corundum. Information technology is a mixture of oxide minerals, typically corundum, magnetite, spinel and/or hematite. It is the most common form of natural corundum that has been used to manufacture abrasives.

The use of emery as an abrasive has declined significantly in the concluding several decades. It has been near completely replaced past manufactured abrasives such as silicon carbide. Silicon carbide has a Mohs hardness of 9 to 9.5. It is inexpensive and usually performs amend than natural abrasives made from corundum or emery.

Corundum every bit ruby, sapphire, and fancy sapphire: Gem-quality corundum is a highly prized and valuable material. When it is bright red in colour it is called "cherry-red." When it is blue it is chosen "sapphire." When colorless it is called a "white sapphire." Gem-quality corundum of any other colour is called "fancy sapphire." In the by, nearly gem corundum was produced in Asia and Australia. In the 1990s, many gem corundum discoveries were made in Africa. All of the stones in this photo were mined in Africa. Nearly all gem corundums are treated by heating or another process to improve their colour.

The best fashion to larn about minerals is to study with a collection of modest specimens that you can handle, examine, and observe their properties. Cheap mineral collections are bachelor in the Geology.com Store. Image copyright iStockphoto / Anna Usova.

Use as a Gemstone

In the gemstone and jewelry market, well-nigh all of the attention goes to a modest group of gems known as "the big 4": diamond, ruby, sapphire, and emerald. Two of these, ruby-red and sapphire, are gem corundums.

These most popular gems are highly sought later on and accept been mined in many parts of the world for thousands of years. Today, millions of rubies and sapphires are required every year to come across the demands of the jewelry market -- from cheap commercial stones sold in malls and department stores to spectacular specimens used in designer and custom jewelry. The need for attractive stones exceeds the abilities of mines to supply. As a outcome, the prices paid for attractive natural stones take risen to high levels.

When a consumer wants a "cherry ring" or a "sapphire pendant," they are by and large non interested in substituting a cherry spinel, blue iolite, or other bonny jewel of similar colour. They want "cherry" or they desire "sapphire." Retail jewelers, specially those selling pieces and sets for under $500, have been increasingly presenting synthetic or "lab-created" gems alongside the natural stones in their brandish cases.

The synthetic materials have the same aluminum oxide composition and crystal structure equally natural rubies and sapphires. Their color is likewise produced by the aforementioned trace elements (chromium for blood-red and iron with titanium for sapphire).

They take the aforementioned optical appeal and ordinarily a better physical appearance than similar-size natural stones of the same toll. As a result, many consumers at present gladly purchase synthetic stones because they receive a more attractive product at a price that they can beget. Over the long term, synthetic gems are probable to keep displacing natural stones from the market place, especially in the lower and middle cost ranges where consumers are very conscious nigh price.

At that place is nothing wrong with selling or purchasing jewelry that contains synthetic gemstones every bit long as 2 weather are met: one) the seller must disclose the fact that the gemstones are products of human being rather than products of nature; and, ii) the buyer conspicuously understands that the gemstones are synthetic and made by people rather than being products of nature.

Corundum spotter bearings: Corundum (cherry-red) bearings in an antiquarian pocket watch with a "jewel" movement. In the early 1900'south, synthetic corundum was being used as the jewel bearings in watches. Image copyright iStockphoto / RobertKacpura.

Corundum bearings: A cartoon of jewel bearings and a capstone (red) holding a pivot wheel in a mechanical watch lubricated past oil (yellow). Public domain image by Chris Burks Chetvorno.

"Jewels" and "Crystals" in Watches

In the mid-1800s, sentry makers in Switzerland needed tiny bearings that were highly resistant to chafe. They discovered that they could drill a hole into a tiny piece of corundum and use it for a smooth-running, long-life begetting. The corundum was much harder than the metals used to make the moving parts of a watch, and information technology was able to stand up up to the continuous abrasion without failing. The corundum bearings were called "jewel bearings" after their gemstone counterparts.

Swiss watches and their "jewel movements" became famous throughout the world for their long life and reliability. In the early 1900s, synthetic corundum bearings replaced natural corundum bearings in nearly Swiss watches. Synthetic corundum was more uniform than natural corundum as well as beingness cheaper and easier to obtain. This use of precious stone bearings created a positive reputation for Swiss watches that continues to this day - fifty-fifty while mechanical watches are being replaced by digital watches.

Synthetic corundum: A boule of synthetic corundum. Considering of its scarlet color, it could be called "synthetic ruddy." Material similar this is used for lookout bearings, gemstones, light amplification by stimulated emission of radiation gain mediums, and many other purposes.

Colorless constructed sapphire is too used in watches. Its durability, vitreous luster, and resistance to being scratched makes it a perfect transparent covering for the face of a mechanical or digital. These clear covers, known as "crystals" protect the confront of the watch from bear upon, dust, wet and abrasion. Constructed sapphire has been used for this purpose for virtually 100 years.

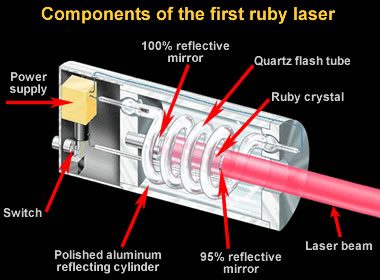

Scarlet laser: Diagram of the first working laser. It employed a sparse ruby crystal every bit its gain medium. Public domain prototype by Lawrence Livermore National Laboratory.

Blood-red Lasers

Synthetic corundum is an essential part of many lasers. In fact, the first working laser was a "ruby laser," fabricated by Theodore Maiman at Hughes Enquiry Labs in 1960. It employed a synthetic cherry-red crystal equally the "gain medium." The proceeds medium is a material in the laser that is the target of an intense burst of light.

That lite causes electrons in the gain medium to jump up to a higher energy level causing the emission of photons, which strike other atoms in the proceeds medium, causing them to exist excited and emit more photons. This brief concatenation reaction produces the very intense low-cal of a light amplification by stimulated emission of radiation axle. Lasers are named after the material used as a gain medium, such as "crimson laser" or "titanium sapphire laser" or "YAG laser" (yttrium aluminum garnet).

In just a few decades, lasers have become mutual items of our society. Tiny lasers are used in CD and DVD players. Lasers are used to cut metal, rock, and other tough materials. Lasers are used to remove tattoos, perform cosmetic surgery, cataract surgery, and LASIK surgery for vision correction.

Synthetic corundum scanner windows: A self-bank check-out machine with a barcode scanner window at a retail store in Houston, Texas. The window of the scanner is probably fabricated from synthetic corundum. Public domain epitome by WhisperToMe.

Other Uses of Corundum

Corundum has many other uses. It is chemically inert and resistant to heat. These backdrop go far a perfect material for making refractory products such as burn brick, kiln liners, and kiln furniture. Today, these products are unremarkably fabricated with constructed corundum.

Pure corundum is colorless, transparent, durable, and scratch resistant. Large crystals of clear synthetic corundum are grown, sawn into thin sheets, and and so used equally the windows of grocery store scanners, watch crystals, shipping windows, and protective covers for electronic devices.

Find Other Topics on Geology.com:

Rocks: Galleries of igneous, sedimentary and metamorphic rock photos with descriptions. |  Minerals: Information about ore minerals, jewel materials and rock-forming minerals. |

Volcanoes: Manufactures about volcanoes, volcanic hazards and eruptions by and present. |  Gemstones: Colorful images and articles almost diamonds and colored stones. |

General Geology: Articles near geysers, maars, deltas, rifts, salt domes, h2o, and much more! |  Geology Store: Hammers, field bags, hand lenses, maps, books, hardness picks, gold pans. |

|  Diamonds: Learn about the properties of diamond, its many uses, and diamond discoveries. |

What Is Corundum Used For,

Source: https://geology.com/minerals/corundum.shtml

Posted by: ransommingenty.blogspot.com

0 Response to "What Is Corundum Used For"

Post a Comment